Welcome to ANDA

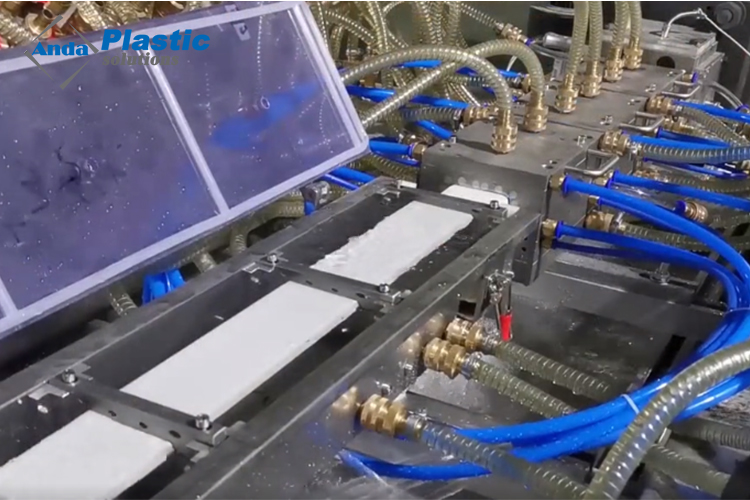

The cooling system of the extruder (along with the heating system) is designed to ensure that the plastic is extruded at the required temperature. During the extrusion process, the friction shear heat generated by the rotation of the screw is often more than the heat required by the material, which will lead to the material temperature in the barrel is too high. If too much heat is not discharged in time, the material (especially the heat-sensitive plastic) will decompose, and sometimes it will make the molding difficult to carry out. To do this, the barrel and screw must be cooled.

1. The cooling of stuff canister

The stuff canister of modern extruder is equipped with cooling system. stuff canister cooling methods are air cooling and water cooling.

Air cooling is soft, uniform and clean. It is widely used in extruder produced at home and abroad. But the fan occupies a large space volume, if the fan quality is not good, it easy to sound. It is generally considered suitable for small and medium extruders.

Compared with air cooling, water cooling has fast cooling speed, small volume and low cost, but it is easy to cause rapid cooling, thus disturbing the stable flow of plastic. If the seal is not good, there will be running, dripping and leakage phenomenon. The cooling system with water pipe wound on the stuff canister is easy to produce scale surface to block the pipe, and easy to corrosion. Therefore, the water used in the perfect water cooling system is not tap water, but chemically treated water. The water is softened and deoxygenated. It is generally considered that water cooling is better for large extruders.

2. The cooling of screw

According to the solid conveying theory, the solid conveying rate is related to the difference between the friction coefficient between the material and the stuff canister, the friction coefficient between the material and the stuff canister. That is, the greater the friction coefficient between the stuff canister and the material, the smaller the friction coefficient between the material and the screw, the more conducive to the transportation of solid materials. In addition to opening longitudinal grooves in the inner wall of the feeding section of the barrel, improving the surface finish of the screw can achieve this goal, but also by controlling the temperature of the barrel and the screw to achieve.

This is because the friction properties of solid plastics are greatly affected by temperature under different conditions. In some cases, for some kind of plastic, the friction coefficient increases with temperature rise and decreases with temperature decline. Therefore, we can control the temperature of the stuff canister and the screw in the solid conveying area to realize the maximum friction coefficient gap between the stuff canister and material, the screw and material. And obtain the maximum solids transport rate.

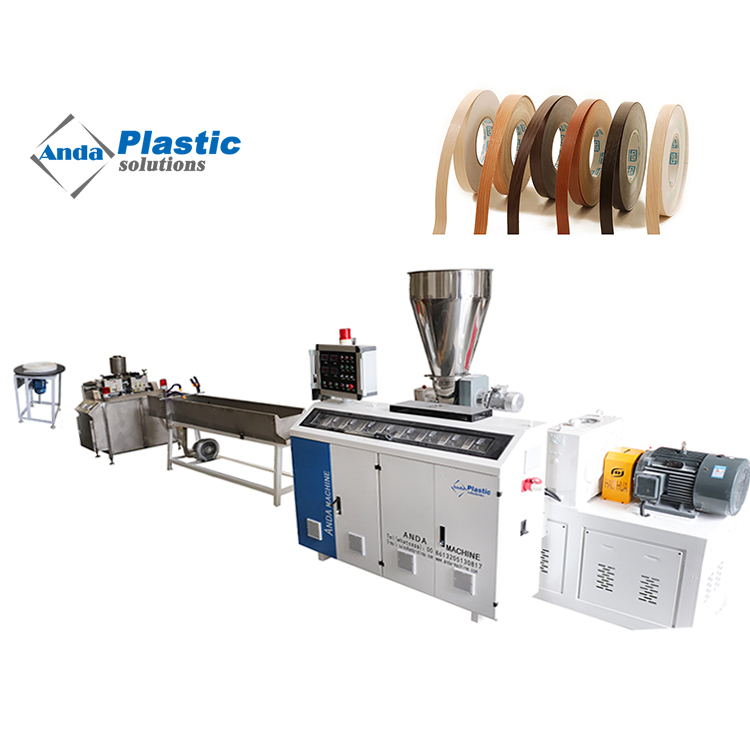

|  |  PVC Ceiling Panel Production Line |