Welcome to ANDA

WPC/PVC foam board extrusion machine is used for the production of PVC foam board with 1220mm width and 3-25mm thickness, density from 0.4-0.6g/cm3. the PVC foam board are mostly used for advertising, furniture, cabinet, partition and and so on.

WPC Foam Board Production Machine Line Manufacturer

The PVC WPC (Wood-Plastic Composite) foam board production line features a next-generation intelligent control system, enabling smarter and more convenient operations. All production data parameters are digitally displayed, facilitating real-time monitoring. The system allows storage, downloading, and printing of production data for analysis, significantly streamlining production management.

Main features of PVC/WPC Foam Board Production Line:

1. equipped with energy saving motor from Nidec company, utp to 30% power saving

2. Adopt world famous brand parts, such as Nidec drive with 5 years warranty, energy saving motor, Omron controller, Siemens PLC touch screen etc, reliable and durable.

3. Adopt specilized PVC foam screw, foaming is uniform and stable.

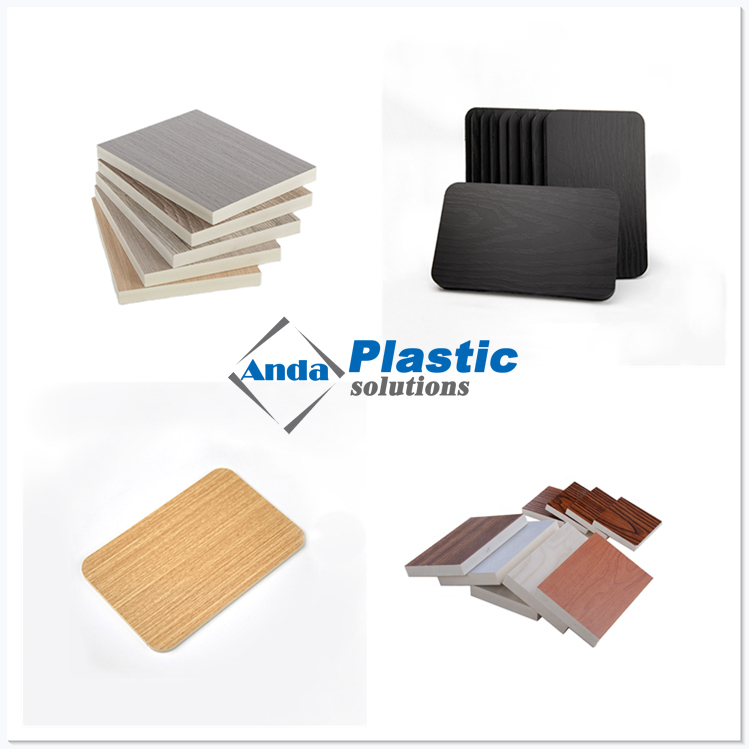

Features of PVC/WPC Foam Board

1. PVC/WPC foam board has the advantages of waterproof, flame retardant, moisture proof, anti-corrosive, moth proof, light weight, sound insulation, heat insulation, resist radiation and aging, etc.

2. PVC/WPC foam board can be made by ordinary wooden processing tools. It also can be drilled, sawed, nailed and excavated. It is the best alternative to the composite products of wood, aluminum.

3. PVC/WPC foam board can be welded as every general welding stipulation and also can be stick to other PVC materials.

Anda providee turnkey solution for PVC/WPC foam board production including technical consultance, machinery, formula and raw material,production support and so on.

Main parameters of WPC/PVCFoam Board Making Machine:

Model | SJSZ80/156 | SJSZ80/173 |

production width | 915/1220mm | 1560/1830mm |

production thickness | 3-25mm | 3-40mm |

Capacity(Max) | 300kg/h | 600kg/h |

Extruder Model | 80/156 | 80/173 |

Parameter:

Model | Applicable thickness | Capacity | Density |

80/156 and 65/132 | 3-20mm | 7.5ton/day | 0.6-0.7 |

80/172 and 65/132 | 3-30mm | 8-12ton/day | 0.6-0.7 |

Layout:

1.WPC/PVC Foam Board Production Line--Extruer

2.WPC/PVC Foam Board Production Line--Cooling Table

3.WPC/PVC Foam Board Production Line--Hauling Machine

4.WPC/PVC Foam Board Production Line--Cutting Machine

5.WPC/PVC Foam Board Production Line--Stacker

6.WPC/PVC Foam Board

Cu Installation site photos:

Installation site photos:

More keywords: PVC foam board extrusion line, pvc foam board machine manufacturers, PVC foam board extrusion machine, WPC Foam board production line,WPC foam board machine,WPC foam board making machine,pvc foam board production line,pvc foam board machine,pvc foam board making machine