Welcome to ANDA

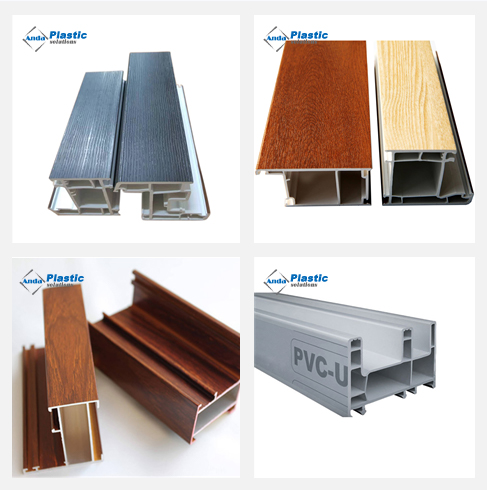

UPVC door and window profile making machine mainly composed by conical twin screw extruder, vacuum calibration table, haul-off machine, cutting machine, stacker. With different moulds, it can produce various UPVC profile, such as: PVC window door profile, PVC wall panel, PVC window sill board, cabinet door board, curtain box, PVC trucking, cable duct, PVC skirting, PVC protection corner and so on.

PVC door and window profile making machine mainly composed by conical Twin Screw Extruder, Cooling Table, Hauling Machine, Cutting Machine, Stacker. With different moulds, it can produce various UPVC profile, such as: PVC window door profile, PVC wall panel, PVC window sill board, cabinet door board, curtain box, PVC trucking, cable duct, PVC skirting, PVC protection corner and so on.

And by changing screw barrel and mould, it can also produce PVC based WPC products, such as: WPC wall panel, WPC window

Technical parameter:

Model | YF180 | YF240 | YF300 | YF600 |

Extruder | 55/110 | 65/132 | 80/156 | 80/156 |

Max applicable width | 180mm | 240mm | 300mm | 600mm |

Motor power | 22kw | 37kw | 55kw | 55kw |

Product Details

1. PVC Door And Window Profile Production Line——Extruder

Extruder adopts PVC ceiling dedicated screw, make sure best plastisizing effect

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed

Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

2. PVC Door And Window Profile Production Line——Cooling Table

Use vacuum system which could better achieve cooling accomplished results.

3. PVC Door And Window Profile Production Line——Hauling Machine & Cutting Machine

Hauling Machine adopt alloy rubber blocks, strictly keep the smooth transition of profile.

Cutting Machine adopt stainless steel material which is wear-resistant and durable. It also equipped with dust cleaner device.

4. PVC Door And Window Profile Production Line——Stacker

5. PVC Door And Window Profile Production Line---Final products

1.World famous brand inverter--ABB, stable and reliable.

2.World famous brand contactor--Schneider, reliable performance.

3.World famous brand temperature controller--Omron, precision temperature control, reliable and durable.

4.Automatically low power consumption: minimum total production line consumption is 25kw/hour.

5. Economical price, which is suitable for large scale investment.

Anda company was established by professional, passionate &responsible peoples who has more than 24 years experience in china plastic machines industry.Since inception, Anda company team always believes that excellent product quality, reasonable price and professional fast service is the basis for long term cooperation with our customers. Therefore, anda company apply very strict rule for quality, and make high standard level for product quality. At same time, we striving to reduce production cost to offer better price to our customers. And, we also pay much attention to service, we consider service as important as sales work, we continuously train our service stuff, improve their service ability and service attitude, so that this team can provide in time, most professional service to each of our customer around the world.

Anda Maxim: Survive by quality! Develop by credit!

Anda mission: endeavor to spread superior quality product made in china to the world, realize the mutual development with customer.