Welcome to ANDA

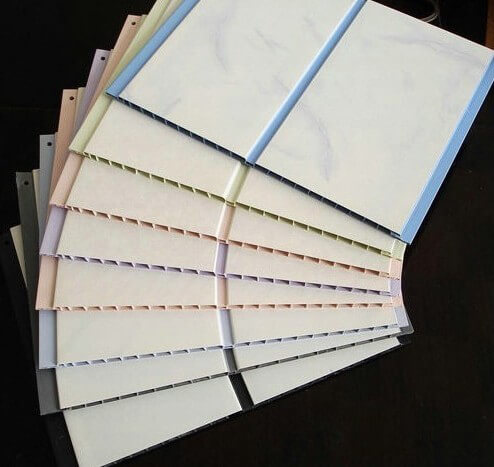

pvc wall panel production line is used to produce pvc wall panel with width normally from 250mm to 300mm with different section shape and height. The surface of pvc ceiling panel can be treated by double by hot stamping printing, or by lamination, which can make marble,wooden design on surface of product.

1. We are expert manufacturer of plastic PVC ceiling panel extrusion manufacturer and can supply you turnkey solution including supplying machines, installation, training staff, material purchasing help, help send Chinese production master etc.

2. We can show you running PVC ceiling production line in our factory and our customer's factory.

3. The most important thing is that we have manufacturing plastic PVC ceiling panel extrusion manufacturer for over 20 years, we are familiar with all production process and we know how to make machines perfect and how to reduce production cost.

Process of plastic PVC ceiling panel extrusion manufacturer:

Mixer → extrusion → surface treatment (including three types: two color printing, hot stamping, and lamination)

According to our formula(main raw material is PVC resin and caco3), raw materials are mixed in the mixer and tranported to the extruder. Through the PVC ceiling extrusion line, panel forming. It you adopt hot stamping and lamination, after extrusion line, your product is finished, But if you adopt two color printing, you can print it offline in the printing machine.

Model of plastic PVC ceiling panel extrusion manufacturer:

Model | 51/105 | 55/110 | 65/132 |

Product width | 160mm/200mm | 250mm,300mm,400mm,500mm | 300mm,400mm,500mm,600mm |

Extruder | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 |

capicity per 24h | >800m2 | >1200m2 | >1600m2 |

Products of PVC ceiling production line: