Welcome to ANDA

Soffit panel machine mainly usded for produce soffit panels .Vinyl siding is a kind of plastic exterior siding for houses and apartment buildings, used for decoration and weatherproofing, imitating wood clapboard, board and batten or shakes, and used instead of other materials such as aluminum or fiber cement siding. It is manufactured mainly from PVC resin, CaCO3 powder and other additives, such as color, opacity, gloss, impact resistance, flexibility, and durability. It is the most commonly installed exterior cladding for residential construction in the United States and Canada. Due to its top layer is covered with PVC, ASA, or PMMA, it can be used in hot, cold dry or wet place, can bear long time sun light, wind, rain and bad weather.

PVC Soffit Panel Siding Panel Machine Production Line

Soffit panel machine mainly usded for produce soffit panels.Vinyl siding is a kind of plastic exterior siding for houses and apartment buildings, used for decoration and weatherproofing, imitating wood clapboard, board and batten or shakes, and used instead of other materials such as aluminum or fiber cement siding. It is manufactured mainly from PVC resin, CaCO3 powder and other additives, such as color, opacity, gloss, impact resistance, flexibility, and durability. It is the most commonly installed exterior cladding for residential construction in the United States and Canada. Due to its top layer is covered with PVC, ASA, or PMMA, it can be used in hot, cold dry or wet place, can bear long time sun light, wind, rain and bad weather.

SJZ65/132-SJZ45/100+YF400 | SJP75/28-SJZ45/100+YF400 | SJP90/32-SJZ55/110+YF400 | |

Max profile width, mm | 400 | 400 | 400 |

Haul off height, mm | 100 | 100 | 100 |

Haul off speed, m/min | 1-8 | 1-10 | 1-20 |

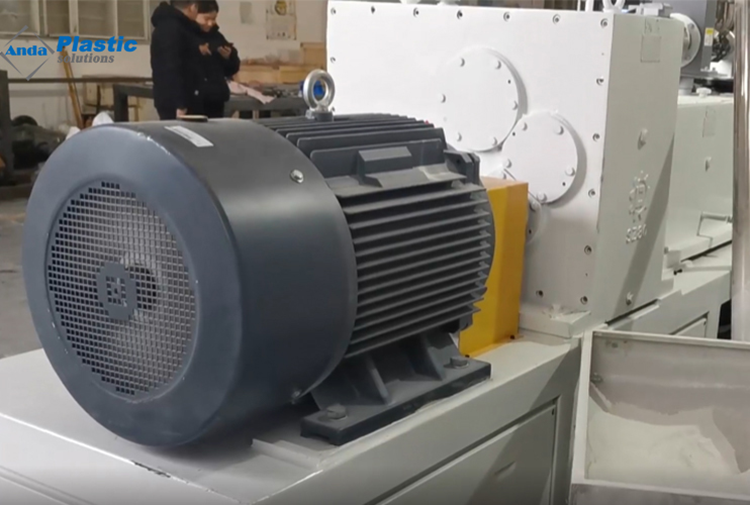

1. PVC Siding Panel Machine --extruder

(1) Adopt Siemens motor (effective control the starting current, lower staring power, reduce voltage fluctuation)

(2) Adopt JC gear box (high efficiency, high bearing capacity, transfer smoothly, compact structure)

(3) Adopt twin screw extruder (which use 38CrMoAL material -- high-wearing, high strength, high temperature resistance, corrosion resistance)

(4) Adopt PID control (temperature fluctuation self adjusting and realize the high automatic level)

2. PVC Siding Panel Machine --cooling table

Adopt vacuum system to help the PVC products fast finalization and guarantee it is not out of shape.

3. PVC Siding Panel Machine --hauling engine

The material of hauling is not too hard which can well protect the transfer of product. It could help the effective traction.

4. PVC Siding Panel Machine --cutting machine

The blade is hard and sharp which has high efficiency and long service time. It also adopt sensing system and easy to cooperate.

5. PVC Siding Panel Machine --stacking machine

Trade Shows

Anda company was established by professional, passionate &responsible peoples who has more than 24 years experience in china plastic machines industry.Since inception, Anda company team always believes that excellent product quality, reasonable price and professional fast service is the basis for long term cooperation with our customers. Therefore, anda company apply very strict rule for quality, and make high standard level for product quality. At same time, we striving to reduce production cost to offer better price to our customers. And, we also pay much attention to service, we consider service as important as sales work, we continuously train our service stuff, improve their service ability and service attitude, so that this team can provide in time, most professional service to each of our customer around the world.

Anda Maxim: Survive by quality! Develop by credit!

Anda mission: endeavor to spread superior quality product made in china to the world, realize the mutual development with customer.