Welcome to ANDA

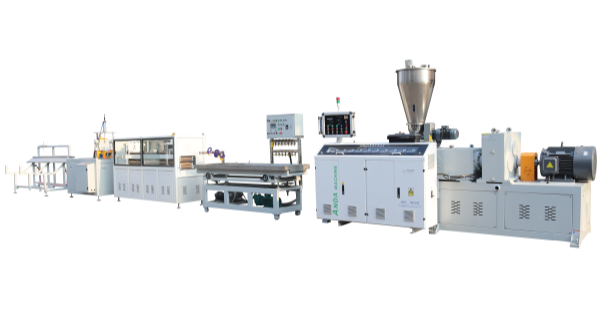

PVC Ceiling tiles extruder machine is used to produce PVC wall panel,PVC ceiling tile etc.The width of PVC wall panel can be 200mm,250mm,300mm,400mm,600mm.

high speed PVC ceiling extruder machine is used to produce PVC ceiling panel, PVC wall panel with width 200mm,250mm,300mm and 600mm with different section shape and height. the surface of PVC ceiling panel can be treated by double color printing & coated with glossy oil, or by heat transfer printing, or by lamination, which can make marble, wooden design on surface of product..

Main Features of PVC ceiling tiles making machines:

1.Speed controlled by inverter, saving power and easy to adjust speed.

2.Extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting.

3.Low power consumption: lowest total production line consumption 25kw/hour.

4.Economical price, suitable for large scale investment.

Process of PVC ceiling tiles extruder machines:

Mixer → extrusion → surface treatment (including three types: two color printing, hot stamping, and lamination)

According to our formula(main raw material is PVC resin and CaCo3), raw materials are mixed in the mixer and transported to the extruder. Through the PVC ceiling extrusion line, panel forming. If you adopt hot stamping and lamination, after extrusion line, your product is finished, But if you adopt two color printing, you can print it offline in the printing machine.

Model of Low price PVC 2 feet by 2 feet ceiling tiles machine / extrusion line:

Model | 51/105 | 55/110 | 65/132 |

Product width | 200mm/250mm | 200mm/250mm/300mm/400mm/500mm | 600mm |

Extruder | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 |

capicity per 24h | >800m2 | >1200m2 | >1600m2 |

1.One year Warranty

2.Engineers avalible to service overseas machinery company

3.Professional seller are always at your service

4.We can provide customer from factory plan,installation,training,formula and so on

Company Information