Welcome to ANDA

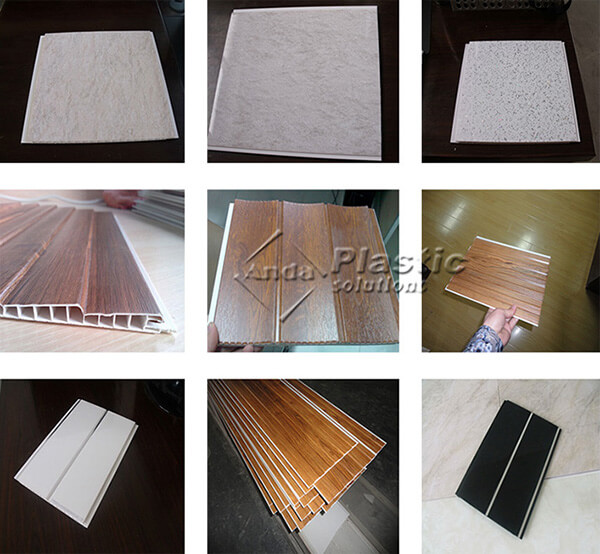

PVC wall panel making machine is used to produce the pvc ceiling panel,pvc wall panel,the width of the panel is from 200mm to 600mm.

PVC wall panel production line is used to produce PVC wall panel with width normally from 250mm to 300mm with different section shape and height.

There are 3 ways to treat the surface of the panels:

1,hot stamp transfer printing

2,double 2 colors printing and UV coating.

3,lamination

By changing the moulds,the pvc ceiling machine can also produce the pvc profiles,pvc edge banding,etc.

Mould of pvc ceiling:

Main parameters of pvc wall decorative panel making machine/production/extrusion line:

| Model | 51/105 | 55/110 | 65/132 |

| Applicable product width(mm) | 160mm/200mm | 250-500mm | 300-600mm |

| Extruder | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 |

| Capacity (m2/24hour) | >800 | >1200 | >1600 |

| Main motor power | 15kw | 22kw | 37kw |

Main Features of pvc wall decorative panel making machine/production/extrusion line:

-- extruder adopts PVC ceiling dedeciated screw, make sure best plastisizing effect, furhter make sure best final product shape

-- extruder speed and haul off speed controlled by ABB frequency inverter, saving power and easy adjusting speed

-- extruder temperature adopt PID control, temperature fluctuation self adjusting, it realise the high automatic level

--the amount of filled calcium can be from 50phr to 250phr

-- Equipped with infrared tracking device which can elimintate the problem of fluctuation of extrusion flow rate, further can make sure get best product

-- lower power consumption,it can save 25-30% electrica power consumption comparing with most same kind PVC ceiling extruder.

--economical price, suitable for large scale investment.

Application of pvc ceiling panel: