Welcome to ANDA

Twin screw extruder is widely used in the fields of polymer blending, exhaust and reactive extrusion due to their excellent dispersing and distributing mixing ability, narrow residence time distribution and excellent self-cleaning.

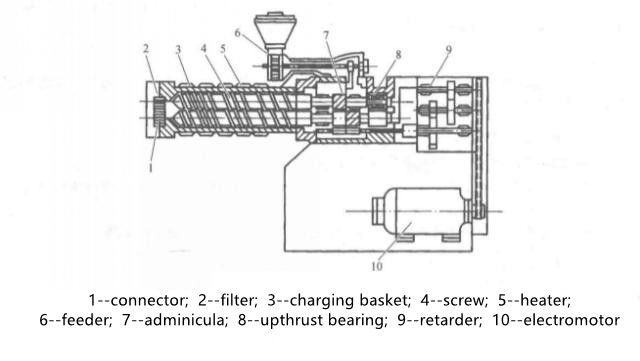

As for twin screw extruder, what do you know about it? Let's start with a picture of the internal structure of it.

Twin screw extruder is mainly composed of the main drive motor, drive system, temperature control system, feeding system, vacuum system, cutting system, conveyor system and so on. The raw material entered into the extrusion machine from hopper to feeding system; then through the temperature control system, materials are heaten, melt and mixed in the extruder; later the waste gas removed by vacuum system and melt are squeezed out at a certain pressure through granulating template. In this equipment, the speed of the main drive motor and the feeding machine can be adjusted and controlled according to the production capacity.

Both the screw and the barrel of twin-screw extruder are adopt advanced "building block" design, screw are made of various types of screw blocks fitted on a mandrel. Depend on the screw block, cylinder lining can be adjusted. Ideal form of screw element structurethus would be made according to technical requirements such as material variety to realize the material conveying, plasticizing, refinement, shear, exhaust, build pressure and extrusion process, and help user better solve the general contradiction of screw. Achieving the goal of one machine multi-purpose, one machine multi-function. Another advantage of the "building block" design is that worn screw and cylinder components can be partially replaced to avoid the entire screw or cylinder scrap, greatly reducing maintenance costs.

The two main applications of twin-screw extruder are extrusion of heat-sensitive materials, such as PVC pipes and profiles; Special polymer processing, such as blending, exhaust, chemical reaction, etc. The twin-screw used for profile extrusion has intermeshing screw edges and grooves, and operates at a lower speed, within about 10r/min. Compared with single screw extruder, its feeding and conveying performance is much better, especially those difficult to feed and easy to slip, such as fibrous, powder and grease materials. The material retention time is short and more uniform, better mixing and large heat transfer area, so that the material temperature control is good, which is particularly important for the processing of heat-sensitive materials.

What are the advantages of the twin screw extruder over the single screw extruder?

1. Twin-screw extruder is mainly used for the production of pipe, plate, granulation and profiled profiles.The output of extrusion molding is more than two times higher than that of a single screw, and the energy consumption is lower than that of a single-screw extruder.

2. Granule production need to be added in single-screw extruder, while because of strong conveying capacity, twin-screw extruder can directly add powder extrusion, save the process of granulation and reduce the cost.

3. The twin-screw extruder has small shearing heat and low requirement on the thermal stability of the special material. It can reduce the dosage of some stabilizers and the toxic effect of the stabilizer, that could also reduce the cost.

4. Compared with the general intermittent or continuous reactor, the twin-screw extruder has the advantages of thinner dispersion layer of molten material and larger melt surface area, which is conducive to the material transfer, heat exchange of chemical reaction and accelerate the reaction processing process.

Because the twin-screw extruder has two screws which has more combinations than the single-screw extruder and can be applied to different product requirements.

(1) From the axes relative position aspect, there are parallel type and conical type;

(2) From the screw engagement procedure aspect, there are engaged type and non-engaged type;

(3) From the screw rotation direction aspect, there are the same direction type and the opposite direction type, in the opposite direction type,which divided into inward and outward;

(4) From the screw rotation speed aspect, there are high speed type and low speed type;

(5) From the screw and barrel structure aspect, there are a whole type and a combination type.

With so many types of products, to make clear the application of products is really important before our buying twin-screw extruder. Hope everyone can find the most suitable product.

As a twin-screw extruder factory, Anda machinery company always use professional service to satisfy the need of all our customers, help everyone get the high quality and low price products. If you have demand, welcome to contact us. If you just have some question about our products, also welcome to contact us. We would like to be your trusted partner.