Welcome to ANDA

PVC ceiling making machine with double screw is used to produce pvc ceiling panel,pvc wall panel etc.The width of pvc ceiling and wall panel can be 20,25,30,40 and 60cm.

By switching mold,it can produce different width in one machine on certain scopes.

pvc wall board production line for interior decoration

PVC ceiling making machine with double screw is used to produce PVC ceiling panel, PVC wall panel with width from 160mm upto 600mm.

the surface of PVC ceiling panel can be treated by double color printing & coated with glossy oil, or by transfer printing, or by lamination, which can make marble, wooden design on surface of PVC ceiling, wall panel.

Together with different moulds, the PVC ceiling making machine with double screw can also produce cornice profile, skirting board, PVC trunking, PVC edge band and so on.

Complete pvc ceiling wall panel making machine / production line with online lamination line is used to produce PVC wall panel with width normally from 250mm to 300mm with different section shape and height. the surface of PVC ceiling panel can be treated by double by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

Production line including:

1.Auto loader for raw material ---1set

2.Extruder---1set

3.Die mould---1set

4.Vacuum cooling table---1set

5.Hot stamping and laminating machine--1set

6.Haul off machine---1set

7.Cutter---1set

8.Stacker---1set

1. PVC wall panel making machine--extruder

(1) Adopt Siemens motor (effective control the starting current, lower staring power, reduce voltage fluctuation)

(2) Adopt JC gear box (high efficiency, high bearing capacity, transfer smoothly, compact structure)

(3) Adopt twin screw extruder (which use 38CrMoAL material -- high-wearing, high strength, high temperature resistance, corrosion resistance)

(4) Adopt PID control (temperature fluctuation self adjusting and realize the high automatic level)

(5) Adopt ABB frequency converter (control and regulate motor speed, stable performance, strong overlord capacity)

(6) Adopt Schneider contactor (high service life, high security)

2. pvc wall panel extruder machine--cooling table

Adopt vacuum system to help the PVC products fast finalization and guarantee it is not out of shape.

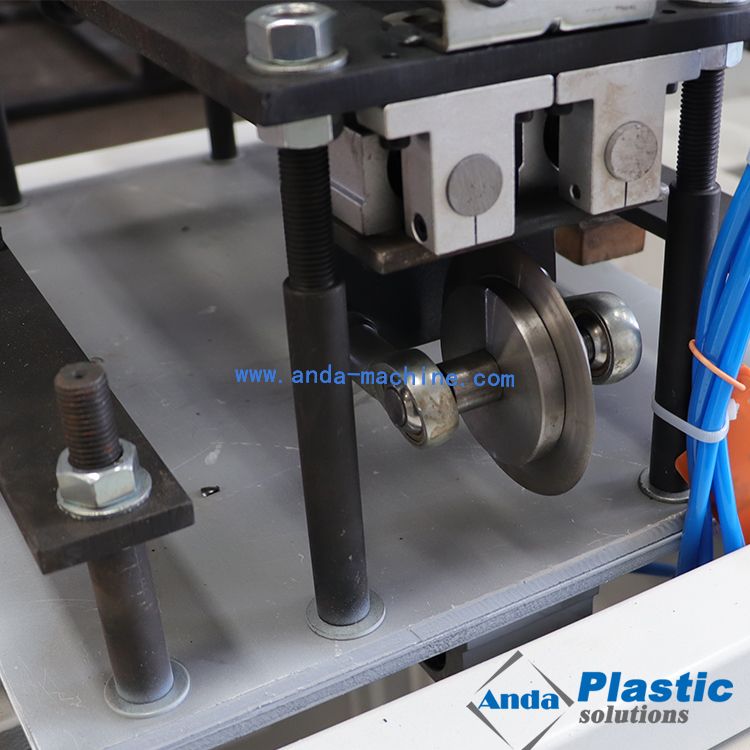

3. pvc panel machine wall panel making--hauling engine

The material of hauling is not too hard which can well protect the transfer of product. It could help the effective traction.

4.pvc wall panel production machine--cutting machine

The blade is hard and sharp which has high efficiency and long service time. It also adopt sensing system and easy to cooperate.

Advantages of our company cheap price laminated pvc wall board production line for interior decoration:

1.We have over 20 years experience in PVC ceiling making machine with double screw

2.We can offer turnkey solutions which includes providing raw material,formula,technical service and stuff training etc.

3.We have agent in Nigeria.Welcome to contact our representative in Nigeria and also can visit customer factory in Nigeria

4.We have sold many machines to Algeria and our engineer have been working there one year all the time

Common Model of PVC ceiling making machine with double screw:

| Model | 48/113 | 55/110 | 65/132 |

| Applicable product width(mm) | 160-200 | 250-500 | 250-600 |

| Extruder | SJSZ48/113 | SJSZ55/110 | SJSZ65/132 |

| Capacity (m2/24hour) | >800 | >1000 | >1600 |

| Main motor power | 15kw | 22kw | 37kw |